Oh boy, here we go again.

@ Kyle Gabriel - Please, please, please put some kind of disclaimer on the site and video so that people understand that the system in your video is a proof-of-concept demonstration and not the end-all-be-all of hydroponics systems. There are far better, less complicated, and MUCH less expensive types of systems, and often they don’t even need any complicated automation or computer control to work just fine. I ran my systems for years with nothing more than a couple of cheap timers for lights and watering pumps and grew lots of veggies and salad greens with no problems.

Hydroponics does NOT need to be complicated.

Hydroponics does NOT need to be expensive.

Especially for first time beginners.

@ infectiousstupidity - Before you decide on a type of hydroponics system to build, first figure out what kinds of plants you want to grow.

There are many types of hydroponics systems.

You should choose one based on what crops you want to grow, and how much you need to grow.

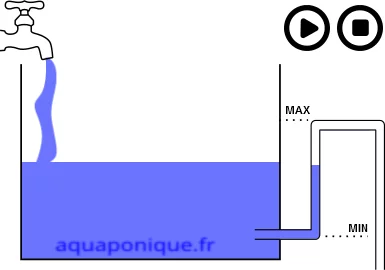

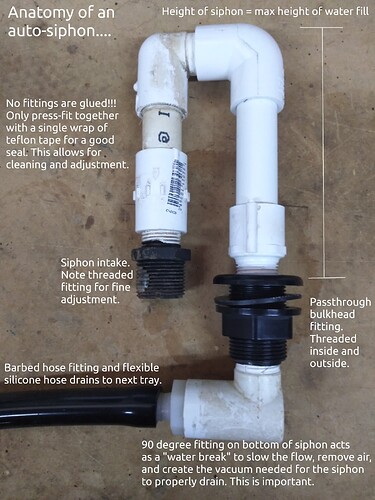

In my experience, the trough-style NFT system is not the best choice.

They tend to leak at all their joint fittings, and you can’t glue those fittings together, because you need to be able to remove the plants and take the whole system apart at least once every month or two to clean out any algae or bio-film growth, otherwise all your plants could die, or you have to use specialized and expensive algaecides that are safe for food use as most algaecides can also damage your plant roots and reduce yields. A trough system also does not use any grow medium, which means there is no physical support for the roots or to hold up your plants once they get bigger. This also means all your roots will get tangled together in the trough and make it impossible to remove the plants for inspection or pruning or cleaning out the system. A trough system also requires that your watering pump is running 24/7, and if the pump fails, your entire crop can die within hours, because there is no grow medium acting as a buffer for water retention. Trough systems are also not very flexible or adaptable to a wide variety of plants, they are best suited to small or short crops like lettuce and other salad greens. If you plan on growing mostly salad greens, a Deep Water Culture, raft type system, or flood & drain table would be better options due to their simplicity, much lower cost, easier maintenance, flexibility, adaptability, and scalability.

As far as combining your hydroponics and mushroom cultivation in one room, that is probably not the best approach. Although Mycodo is fully capable of running multiple “zones” or grow spaces simultaneously, your mushroom fruiting chamber probably should be isolated or separated from the hydroponics part of the system because the mushroom chamber will need to run at slightly lower temperatures and much higher humidity than the hydroponics. Running the hydroponics at the same temp and humidity as the mushroom chamber will invite mold growth which could destroy your entire plant crop very quickly. You will also probably want to vent the mushroom fruiting chamber out of the room or directly to the outside of the house to prevent any possible humidity and spore buildup in your house or hydroponics area.

Mycodo will run on most systems that can support Debian-based OSes, but If you plan on NOT using a Raspberry Pi, you may end up having problems if you need to use any direct-connected sensors since there will be no GPIO bus. You can connect sensors to an ESP32 and send telemetry over your LAN via MQTT, or add a 3rd party GPIO bus device, but you will probably have to do all of the custom programming to make it work with Mycodo since I believe Mycodo is currently only setup to work with the Raspberry Pi GPIO and a few other GPIO-compatible SBC devices. This also goes for any of your outputs, you will have no way of directly-wiring your output control relays to your server, and will have to use a 3rd party GPIO device or control outputs via WiFi using ESP32s running Tasmota or other custom-programmed firmware. This raises the possibility of reliability problems due to WiFi connection issues, and there is also always lag-time to deal with even on your LAN.

Again, keep in mind that the system in the video is more of a proof-of-concept than anything else. It shows what you can do if you want to take it as far as possible. If you are growing simple crops like salad greens, you absolutely do not need a nutrient metering / mixing system with all those peristaltic pumps that need to be calibrated. You will need to mix a new tank of nutrients once every 2-3 weeks or so, and that only takes about 15-20 minutes to do by hand. That’s also when you would want to clean out the tank and the rest of system and remove any sediment, algae, or bio-film buildup. You also don’t need an automated pH control system. Measuring and adjusting pH only takes a minute to do by hand, and you only need to check it every 2 or 3 days. PH meters are expensive, do not last very long, and require constant calibration and careful storage using special test solutions (another extra cost). It is much cheaper and easier to check pH by hand. I guarantee you that a $16 8oz. bottle of pH test drops will probably outlast most $100-$200 pH meter probes (since they are not designed for constant submersion). The ones designed for constant submersion cost about $400 and up just for the probe. If you were setting up a large industrial-scale greenhouse for commercial crop production, you would probably want these automation systems, but for a small scale system they are not cost effective, and are often more trouble than they are worth, especially if you are just growing salad greens.

Just some things you should really consider before you go out and start buying stuff